The Indiana Dunes is a 2,000-acre state park surrounded by an even larger national park, encompassing 15,000 acres of beaches, prairies, wetlands, savannas, and forests. The dunes, which are essentially massive mounds of sand reaching nearly 200 feet high, were formed when glaciers passed through the Indiana Dunes area over 14,000 years ago.

- Blast Furnace at ArcelorMittal. Photo courtesy of ArcelorMittal

But if you look closely enough, you’ll see nature coexisting with the steel plants and other industries. The Indiana Dunes area is home to Cleveland Cliffs, U.S. Steel’s Midwest Plant, and other steel companies. And located between ArcelorMittal and U.S. Steel’s Midwest Plant is the Port of Indiana, which handles more ocean-going cargo than any other U.S. port on the Great Lakes.

Although tours are not currently available for visitors, the steel mills can be viewed by driving along U.S. 12 from Chesterton to Portage.

See Sand and Steel Along the Shore

A good place to stop and see the mix of industry and nature is Portage Lakefront and Riverwalk, a 57-acre lakefront site that features a sandy beach and a handicap-accessible riverwalk and fishing pier. Just to the east of Portage Lakefront and Riverwalk is U.S. Steel.

- A glimpse inside ArcelorMittal. Photo courtesy of ArcelorMittal.

Another spot to get a glimpse of the industry is the Port of Indiana, which the public can visit by presenting identification at the security gatehouse at the entrance. There is a public access area for birdwatchers and people who like to see steel mills and ships coming from across the world. Tons of products and materials go in and out of the port via barges, trains, and trucks each year. And for a panoramic overview of the overall landscape, take The 3 Dune Challenge at Indiana Dunes State Park and see the sights from the three highest dunes at the state park.

In much of the rest of the Indiana Dunes National Park and Indiana Dunes State Park, it is easy to get in the middle of a forest or in the middle of towering sand dunes —away from other people or signs of the industry—and forget you’re anywhere near civilization.

But local steel—which is in the vehicles on our roadways, the bridges that hold those vehicles, the artwork we admire, the appliances we use, and the skyscrapers visible if you peer across Lake Michigan toward Chicago—is part of what makes the Indiana Dunes area unique.

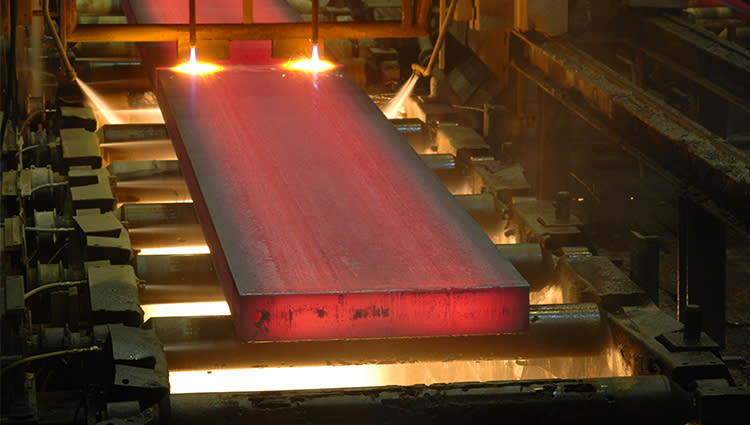

- Continuous caster. Photo courtesy of ArcelorMittal.

And stay tuned. The area’s steel heritage may someday be preserved in a museum located in the heart of Indiana Dunes.

Steelmaking 101

At mills like ArcelorMittal in Burns Harbor, iron ore pellets from mining operations are brought in by freighter or rail along with coal, which is baked to turn it into coke.

The iron ore, coke, and limestone are joined in a 4,000-degree Fahrenheit blast furnace, with slag rising to the top (and being taken away for use in paving and concrete) and the molten iron (the usable product) sinking to the bottom and being transferred to huge ladles. Sulfur is inserted to draw out more slag, which is scraped off.

The molten iron is poured over scrap metal, then pure oxygen is blown into the basic oxygen furnace. The resulting product is steel. Of course, scrap metal can be directly melted into new steel in an electric arc furnace.

The molten steel goes into casting to be made into slabs or billets. The slabs and billets go to primary forming, where they become coils, rods, and cables. The products then move onto finishing to be further transformed to meet the needs of the end-user, to remove blemishes, and to be coated.

Note: Mills like U.S. Steel’s Midwest Plant are finishing facilities.